Carbonizer machine is the equipment for making charcoal from solid or organic matter. The whole charring process is going in the condition of isolation or lack of air. Materials pyrolysis into charcoal, smoke, tar, vinegar, etc.

Raw materials for carbonizing

Our carbonization furnaces are mainly used for making charcoal. The common materials for carbonizing are biomass, such as natural wood, timber, branch, bamboo, coconut shell, rice husk, palm shell, sawdust briquettes, etc.

Carbonization Process

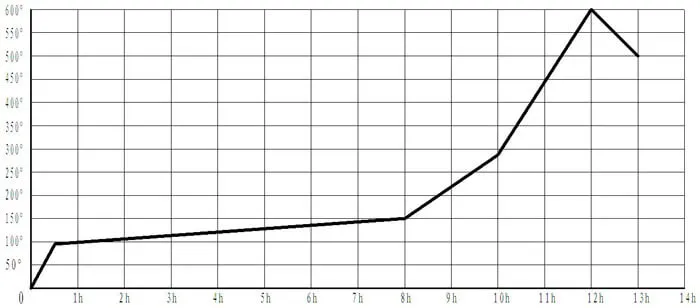

The carbonization process can be roughly divided into the following five stages.

1st stage: Drying and dehumidifying stage

The temperature at this stage is 120-150 ℃, and the pyrolysis rate is very slow. The moisture in the wood relies on external heat to evaporate, and the chemical composition of the wood material hardly changes.

2nd stage: Pre-carbonization stage

The temperature at this stage is 150-280 ℃. The pyrolysis reaction of wood materials is obvious, and the chemical composition of wood materials begins to change. Among them, unstable components such as hemicellulose pyrolysis generate carbon dioxide, carbon monoxide, and a small amount of acetic acid.

The above two stages require an external heat supply to ensure the rise of pyrolysis temperature, so it is also called the endothermic decomposition stage.

3rd stage: Carbonization stage

The temperature in this stage is 280-400 ℃. In this stage, the wood material accelerates pyrolysis and generates a large number of decomposition products. The produced liquid product contains a large amount of acetic acid, methanol, and wood tar. The carbon dioxide content in the produced gas product gradually decreases, while the flammable gases such as methane and ethylene gradually increase.

This stage emits a lot of reaction heat, so it is also called the exothermic reaction stage.

4th stage: Calcination stage

The temperature rises to 400-600 ℃. At this stage, the charcoal is calcined to discharge the volatile substances remaining in the charcoal and increase the fixed carbon content of the charcoal.

At this time, very little liquid product is produced.

5th stage: Cooling after carbonization

The charcoal can only be taken out when the temperature drops to below 50 ℃, otherwise, the charcoal may reignite or scald the operators.

The above five stages roughly describe the whole process of carbonization. For different types of carbonization machines and different materials, there are many differences in operation and temperature changes.

Please click on the below introduction of each type of furnace for more details.

Airflow Carbonization Furnace

Airflow carbonization furnace produces charcoal from sawdust briquettes, wood, bamboo, coconut shells, rice husk, agro wastes, etc. The flue gas generated during the carbonization process will flow through the duct to the combustion zone, and then be ignited, and the subsequent carbonization only needs to burn these gases to complete. That's [...]

Horizontal Carbonization Machine

Horizontal carbonization machine is a new type of charcoal-making equipment. It adopts a horizontal design to reduce machine height. So it is more convenient for loading raw materials. Same as other airflow carbonization furnaces, it also includes a smoke recycle system. Smoke generated in the carbonizing process enters the purifier and [...]

Carbonization rotary kiln

What's carbonization rotary kiln Carbonization rotary kiln is a newly designed machine for making charcoal. Comparing with the airflow carbonization furnace, its greatest feature is to produce charcoal continuously, not batch production. The entire charcoal production process is smokeless, and no pollution to the environment. Structure of rotary carbonization [...]