Charcoal Briquette Machine Brief Introduction

Charcoal briquette machine refers to the equipment for compressing charcoal powder or coal dust into different shape blocks. According to the different briquetting principles and briquette shapes, we divide them into 4 types, charcoal briquette extruder, pillow charcoal machine, shisha charcoal press machine, and honeycomb coal briquette machine.

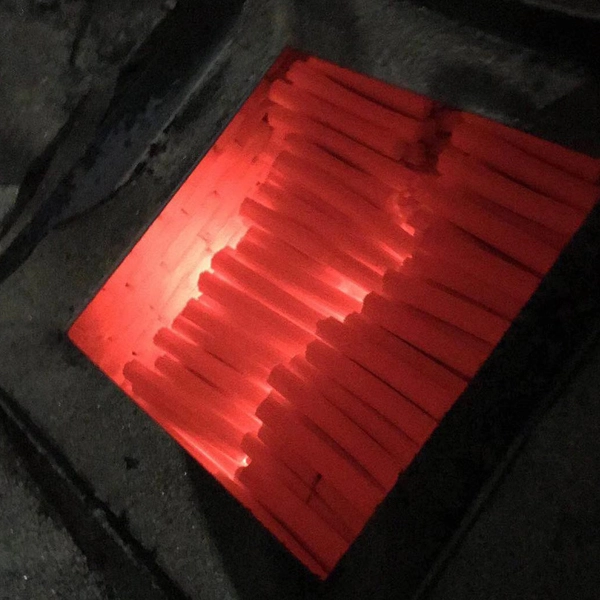

Charcoal Briquettes Application

Charcoal briquettes are mainly used as solid fuel in both households and industries. You can see them used for roasting meat on the BBQ grill, burning on the household stove for cooking, heating the industrial boiler in factories, etc. It is a good business for producing charcoal briquettes.

How to get charcoal/coal materials for making briquettes

- Waste charcoal or coal dust. In the charcoal production plant or coal mine, there is a lot of waste charcoal/coal in small pieces and dust. These waste charcoals can be collected and used for making briquettes. It is not only a good way to get cheap materials for making briquettes, but also turn the waste into wealth, increasing the level of resource utilization.

- Make charcoal from biomass materials, such as waste wood, branches, coconut shells, rice husks, bamboo, palm shells, etc. You need to build a charcoal kiln to produce charcoal or use the carbonization furnace for charring the biomass materials into charcoal.

Requirements of charcoal for making briquettes

- Size. The charcoal or coal size should be less than 5mm so that they can be easily pressed into briquettes. For some large-sized charcoal such as lump charcoal, coconut shell charcoal, etc., it is necessary to use a charcoal crusher to crush it into powder before proceeding to the next step of mixing.

- Moisture. The moisture of charcoal for making briquettes is around 30%. Proper moisture is good for the briquettes forming and increasing the density of the charcoal briquettes.

- Biner. Usually, the binder is necessary for the charcoal briquettes processing. Binder can make the charcoal briquettes more solid and smooth. The most common binder is corn starch or cassava starch. The best binder adding rate is 4%-6%. There are also some customers who add the combustion improver to accelerate the lighting speed of charcoal. No matter binder or ignite accelerating agent, you can use a charcoal mixer to blend the charcoal powder with water and additive evenly.

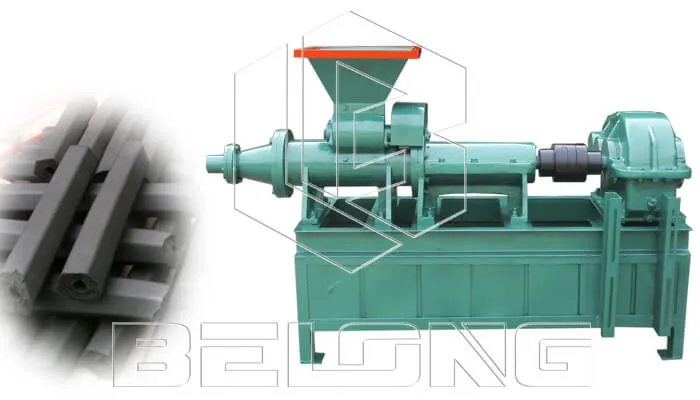

Charcoal Briquette Extruder Machine

The charcoal briquette extruder machine adopts spiral extrusion molding. It mainly includes the machine base, bearing seat, spiral shaft, cylinder body, discharge port, and mold. The whole set briquette extruder machine is driven by an electric motor. The common mold shape is hexagonal, octagonal, square, and round. Besides, the briquette core can be solid or hollow.

Technical parameters of charcoal extruder machine

| Model | Power | Capacity | Dimension | Weight |

|---|---|---|---|---|

| BLTB-140 | 11kW | 400-600 kg/h | 2*1*1.1m | 700kg |

| BLTB-180 | 18.5kW | 800-1000 kg/h | 2.4*1.2*1m | 1000kg |

Briquette cutter and spare parts of charcoal extruder machine

How the extrusion briquette machine work

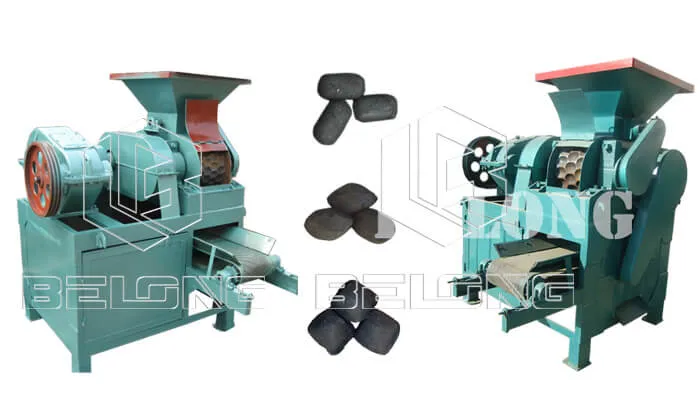

Pillow Charcoal Machine

Pillow charcoal press is a roller-type charcoal briquette machine. It can convert charcoal/coal powder into oval shape and pillow shape briquettes. This machine includes two press rollers and the roll grooves can be customized to produce different shapes and sizes of coal briquettes. Charcoal briquettes are solid and convenient for packing and transportation. They are widely used for barbecue, grilling, cooking, refractories, power plants, and metallurgy.

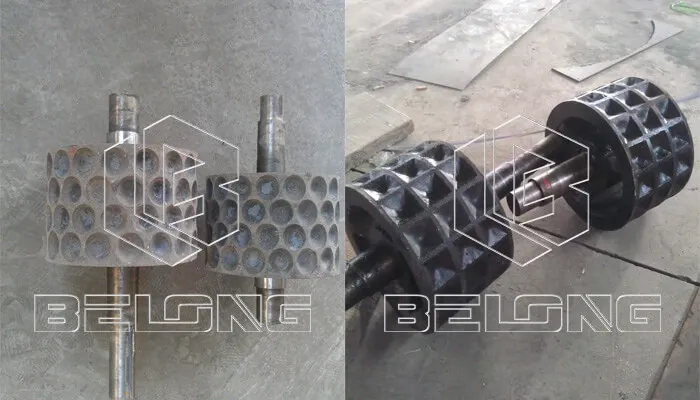

Press Roller of charcoal press machine

The common shape of the mold is oval shape and pillow shape. If you want to know more about spare parts for pillow charcoal machines, you can read the blog Coal Briquette Machine Press Roller

Technical parameters of coal briquette press

| Model | Power | Capacity | Dimension | Weight |

|---|---|---|---|---|

| BLYQ-290 | 5.5kW | 2-3t/h | 1250*1250*1400 mm | 650kg |

| BLYQ-360 | 7.5kW | 3-4t/h | 1500*1500*1800 mm | 900kg |

| BLYQ-430 | 11kW | 4-5t/h | 2100*1700*2100 mm | 3000kg |

Pillow charcoal briquette machine working video

Shisha Charcoal Machine

Shisha charcoal machine adopts a double-pressing design. It consists of a set of molds arranged in a tray. When the machine is working, the mold rotates and compresses the charcoal powder into a tablet or cube shape.

Shisha charcoal machine working video

Honeycomb Coal Briquette Machine

Honeycomb coal briquette machine can compress small granular coal and dust into coal blocks with holes. Its mold can be changed easily to produce cylindrical shapes and square shape briquettes. The coal briquette diameter range is 90-250mm with different hole quantities. Honeycomb coal is widely used as household fuel for cooking.

Honeycomb Coal Machine Working Video

Parameters of honeycomb briquette machine

| Model | BLMQ-120 | BLMQ-140 | BLMQ-160 | BLMQ-220 |

|---|---|---|---|---|

| Capacity | 45pcs/min | 45pcs/min | 45pcs/min | 45pcs/min |

| Honeycomb coal briquette diameter | φ100-φ120mm | φ100-φ140mm | φ100-φ160mm | φ180-220mm |

| Coal briquette height | 70-80mm | 70-80mm | 70-80mm | 70-80mm |

| Power | 5.5kW | 7.5kW | 7.5kW | 11kW |

| Belt rotating speed | 406r/min | 406r/min | 406r/min | 406r/min |

| Dimension | 1280*1160*1750mm | 1320*1260*1850mm | 1400*1300*2000mm | 1580*1450*2200mm |

| Weight | 1200kg | 1400kg | 2000kg | 4000kg |