Safety matters in charcoal production

Charcoal production involves multiple processes and equipment. While we pay attention to the quality and efficiency of charcoal production, we must not ignore safety matters in production. It can be said that safety matters are the most basic and important part of production. Often a small negligence will cause irreparable losses to workers and factories. [...]

Palm Kernel Shell Charcoal Production

Palm kernel shell (PKS), derived from the fruit of the palm tree - palm fruit. In the process of refining palm kernel oil, the kernel is first extracted from the pulp, and then the outer shell of the kernel is peeled off. The hard outer shell is the palm kernel shell. Palm kernel shells have [...]

Rotary dryer for wood shavings shipping to USA

Rotary dryer, also known as rotary drum dryer, is mainly used to dry various biomass raw materials in biomass briquettes production, such as sawdust, rice husk, bagasse, etc. The dryer used for drying wood shavings is a single-channel rotary dryer, which is made by slightly modifying the conventional sawdust dryer. It has high thermal efficiency, little [...]

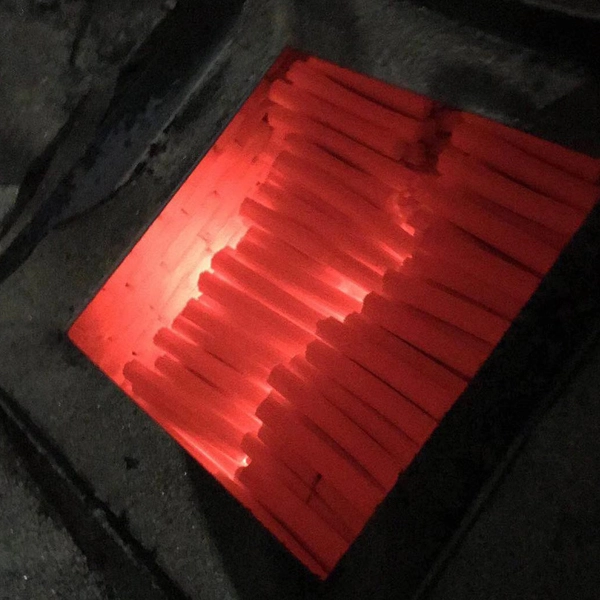

How to make BBQ charcoal

How to make BBQ charcoal? For many people who want to try to produce BBQ charcoal, this is the first question before them. With the popularity of barbecue all over the world, the market demand for BBQ charcoal has also increased, and the business of producing BBQ charcoal has gradually attracted the attention of investors. [...]

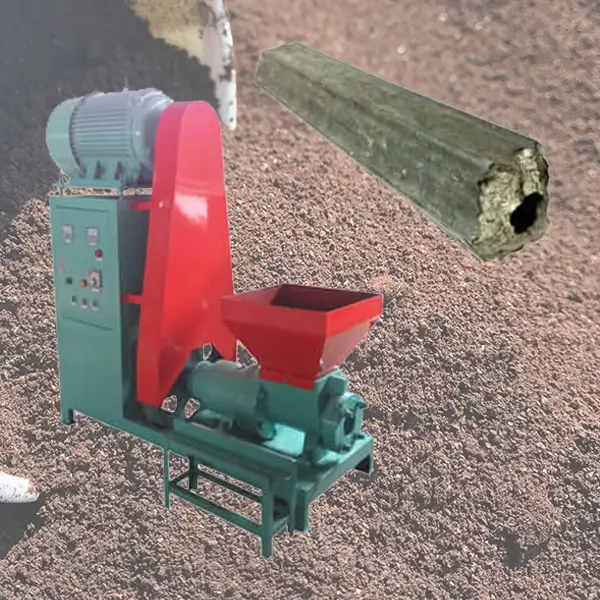

Small scale charcoal making

Small-scale charcoal making is a simple process that is suitable for homemade or new hands to start a charcoal production business. It usually consists of several small machines or even only one machine. Customers can start charcoal production soon without much installation work. Low investment, quick benefit. It is friendly for customers which have a [...]

Coffee briquette machine

Coffee briquette machine is also called the coffee logs press. It can transform the coffee wastes into solid bio-fuel logs without any binding agent. Coffee grounds needs to be mixed with at least 50% sawdust to make briquettes. How to make coffee briquettes First step: Crushing coffee husk Common [...]

What’s the best materials for making charcoal briquettes

Good raw materials are the basis for the production of high-quality charcoal. In theory, many biomass can be used to produce charcoal, such as sawdust, bamboo powder, rice husk, bagasse, and so on. But it needs to be clear that under the same conditions, the quality of the carbon produced by different materials is different. [...]

BBQ Charcoal Briquettes Plant

BBQ charcoal briquettes plant includes a complete charcoal-making process from raw materials carbonizing to charcoal briquettes production. BBQ charcoal is a hot sell on the market. It has the features of smokeless, less ash, longer burning time, and better commodity attributes. BBQ charcoal briquettes production process The process is Materials→carbonizing→crushing→mixing→briquetting. A complete BBQ charcoal briquettes production [...]

Biomass Charcoal Briquettes Plant

Biomass materials for making charcoal Biomass materials include forest wastes, agricultural wastes, etc. Materials like coconut shells, waste wood, branches, bamboo, etc can be carbonized into charcoal directly. Some materials like sawdust from sawmills, furniture factories, bamboo sawdust from toothpick factories, etc, are not suitable for carbonization directly. How to make charcoal from sawdust? [...]