The production of biomass briquettes requires the humidity of raw materials to be less than 15%, so raw materials whose humidity does not meet the standard need to be dried. Customers choose the appropriate model of dryer based on the humidity and output of the raw materials.

The humidity of the produced charcoal briquettes is about 30%, and they need to be dried before use or packaging.

Sawdust dryer

The sawdust dryer is specially designed for drying the biomass materials, such as wood sawdust, small wood chips, rice hull, sunflower husk, peanut shells, etc. Depending on the different drying principles, sawdust dryers are classified into two types, sawdust flash dryers, and rotary drum dryers. Why the sawdust [...]

Charcoal briquettes mesh belt dryer

Mesh belt dryer is also called a chain plate dryer. It is a kind of continuous charcoal briquettes drying machine. This dryer is widely used in metallurgy, building materials, chemical, food, and other industries. The stainless steel mesh belt dryer is also an ideal equipment for the drying [...]

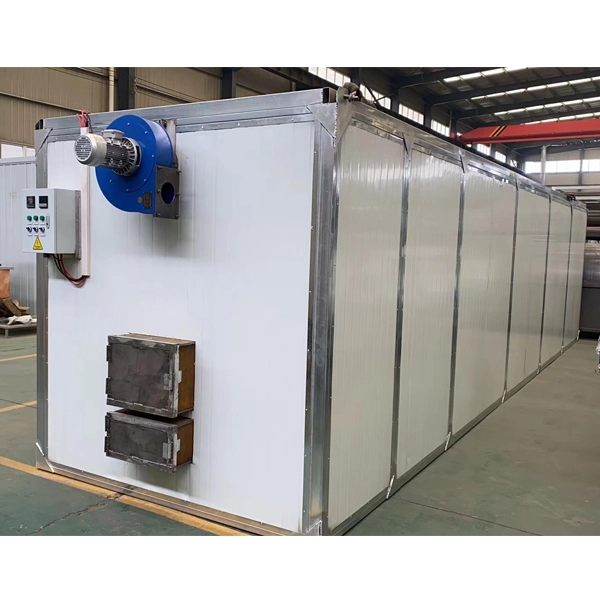

Box Type Charcoal Briquettes Dryer

Box-type charcoal briquette dryer is used to reduce the moisture of charcoal briquettes. It is a batch dryer consisting of thermal insulation boards, trolleys (optional), trays (optional), fans, an electric control panel, etc. As its appearance looks like a container or a room, it is also called a [...]