What are hookah coals

Hookah coals are used for heating the tobacco in hookah smoking. Hookah is also called shisha, Nargile, and hubble-bubble in different countries and areas. With the popularity of hookah around the world, the demand for hookah coals is rising fast. You can find them on the shelves of many supermarkets and online shops. So if you want to start or extend your charcoal business, it is a good choice to produce hookah coals.

How are the hookah coals made? I think It will take you a lot of time to gather the information. Fortunately, we have done this tough work for you. In the article, we will tell you how to make the best hookah coals from the selection of raw materials to the hookah charcoal packing.

Best materials for making hookah coals

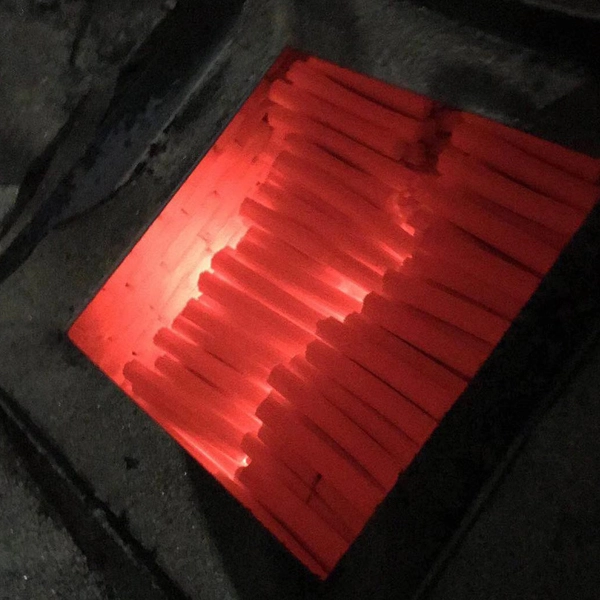

Most of the hookah coals on market are made from coconut shells and fruitwood. Different from the other ordinary biomass charcoals, hookah coals must be smokeless, odorless, have low ash residue, long burning time, have consistent heat, etc. So we can only choose the raw material from hardwood, coconut shells, fruit trees, etc.

Production process of shisha charcoal

About the production process of shisha charcoal, there is not much difference with other charcoal briquettes production. Carbonization–charcoal grinding–mixing with binder–compress hookah charcoal–hookah coals drying–charcoal packing.

Recommended carbonizing machine

We recommend the hoisting type carbonization furnace. Its cost is low, installation and operation are simple. Especially the vertical loading is perfect for coconut shells, wood chips, etc.

What kind of binder can be used for shisha charcoal

Because carbon powder has no plasticity, it must be formed by adding a binder. For hookah charcoal binders, we do not recommend chemical agents, as they will produce harmful gases after burning. Commonly used are corn starch, potato starch, tapioca starch, and so on. You can choose the cheapest starch as the binder based on the price of these starches in your local area. When using starch as a binder, please note that it must be gelatinized first(cook starch into a paste), and then mixed with charcoal powder. For 100 kg of charcoal powder, 3-5 kg of gelatinized starch is added.

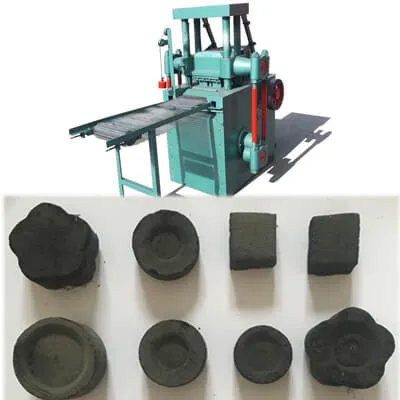

Choose the right shisha charcoal machine upon the shape of hookah coals

Mechanical shisha charcoal press machine is for producing oblate and cube shisha charcoals

Charcoal extruder machine for producing finger coals and cube hookah coals

Shisha charcoal packing machine

Package is not only the last step but also an important work of shisha charcoal production. You can find that the hookah coals sold on market are all with nice package. It is a not a easy work for the workers to pack these small cubes or circle hookah coals. The hookah coals packing machine will liberate the workers from this difficult task.