Rice husk charcoal is formed by insufficient combustion of rice husk when heated to below its ignition temperature. Rice husk is the outermost part of the rice seed which is a hard layer and a waste material from rice milling. Therefore, the raw materials for producing rice husk charcoal are abundant and low in cost. Making rice husk charcoal is a low-cost and high-yield business.

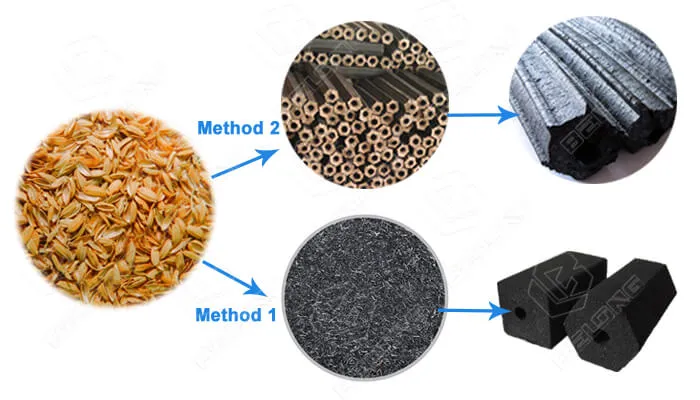

There are two ways of making charcoal from rice husk, one is directly carbonizing rice husk into charcoal through a carbonization furnace, and then compressing the rice husk charcoal into briquettes. The other is to compress rice husk into briquettes first by the rice husk briquette machine, then carbonize the rice husk briquettes into charcoal. Here we will introduce these two rice husk charcoal-making processes separately.

Carbonize rice husk to charcoal firstly

There are two ways of carbonization, one is carbonization by a traditional charcoal kiln, and another is carbonization by machines. Here we focus on the production of rice husk charcoal by machines.

Compared with the traditional carbon cellar, the carbonization machine has the advantages of less labor intensity, shorter carbonizing time, smokeless, and higher charcoal yield.

We have different types of carbonization furnaces that can be used for carbonizing rice husks. For small or medium-scale charcoal production, vertical-type carbonization furnace and horizontal-type carbonization furnace is recommended. For the large capacity of rice husk charcoal production, you can choose the continuous carbonization machine (rotary carbonizer).

Uses of rice husk charcoal

In addition to being used as fuel, rice husk charcoal is also widely used in industry and agriculture.

- In industry, rice husk charcoal can be used as a thermal insulation material for steel production, and it can also be used as a raw material for steelmaking auxiliary materials.

- In agriculture, it can be used as fertilizer and soil improvement for the cultivation of vegetables, flowers, seedlings, fruit trees, and other crops.

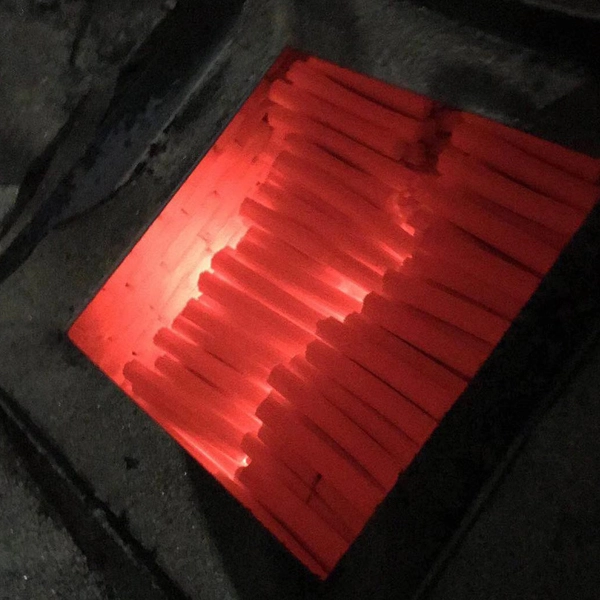

- In daily life, it can be used as clean energy for cooking and heating. Since the rice husk charcoal is directly carbonized into a pulverized state, it needs to be further shaped into briquettes for ease of use.

How to make rice husk charcoal briquettes

After rice husk is carbonized into charcoal, we need to use a charcoal briquette machine to make charcoal briquettes. We have 4 types of charcoal briquette machines for making different shapes of briquettes from rice husk charcoal.

Please read the below article for details of the charcoal briquette machine

Make rice husk briquettes first

Rice husk is rich in cellulose and lignin, so it can be made into briquettes by a rice husk briquette machine. Due to the small size of the rice husk, it does not need to be crushed. Therefore, the process of making charcoal from rice husks is the same as that of making charcoal from sawdust.

The following is a detailed article on charcoal production from sawdust, the whole process is also applicable to rice husks.

The advantages and disadvantages of the two production processes of rice husk charcoal

- 1

The advantage of carbonizing rice husk first is that it can produce rice husk charcoal briquettes in different shapes.

The disadvantage is that the output is relatively low. For the same carbonization furnace, the output of carbonized rice husk is lower because the bulk density of rice husk is low and the filling weight is small.

- 2

The advantage of converting rice husk into rice husk briquettes first is that the charcoal yield is higher and the quality of the finished charcoal is better.

Because the density of rice husk briquettes is >1, the same carbonization furnace can hold heavier rice husk rods, and the charcoal yield will naturally be higher. As for the quality of the finished charcoal, it is because no additives are added during the entire production process and the ash content is lower. And in the last step of carbonization, the moisture of the finished charcoal is lower.The disadvantage is that the finished product can only be in the shape of a hexagonal prism or square prism.