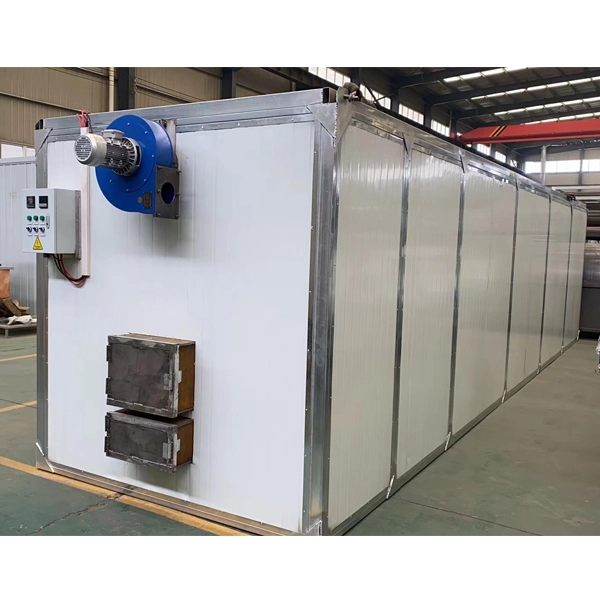

Mesh belt dryer is also called a chain plate dryer. It is a kind of continuous charcoal briquettes drying machine. This dryer is widely used in metallurgy, building materials, chemical, food, and other industries. The stainless steel mesh belt dryer is also an ideal equipment for the drying and processing of food and vegetables.

Working Principle of Charcoal Briquettes Mesh Belt Dryer

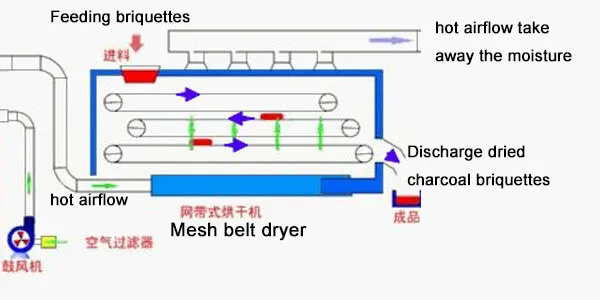

The main working principle is to evenly spread the charcoal briquettes on the mesh belt. The mesh belt is driven by the transmission device to move back and forth in the dryer. The mesh belt adopts 12-60 mesh steel wire mesh. The hot air flows through the charcoal briquettes, and the water vapor is discharged from the vent, so as to achieve the purpose of drying.

Box body of the mesh belt dryer is composed of standard sections. In order to save space, the dryer can be made into a multi-layer type, with a length of 6-40m and an effective width of 0.6-3.0m. The main heating methods of the mesh belt dryer are electric heating, steam heating, and hot air heating.

Feature of Charcoal Briquettes Mesh Belt Dryer