Drum chipper is a specially designed equipment for producing wood chips. It is widely used in the material preparation section of wood chip mills, particleboard, fiberboard, paper mills, biomass fuel plants, etc.

The raw materials processed by the drum chipper are mainly logs, waste wood, wooden pallets, building templates, nailed boards, wood cutting residues (branches, twigs, etc.), and wood raw material processing residues (slabs, slats, round wood cores, waste veneers, etc.), which can also be used to cut non-wood materials (such as sugarcane, reed, bamboo, etc.).

Drum chipper design structure

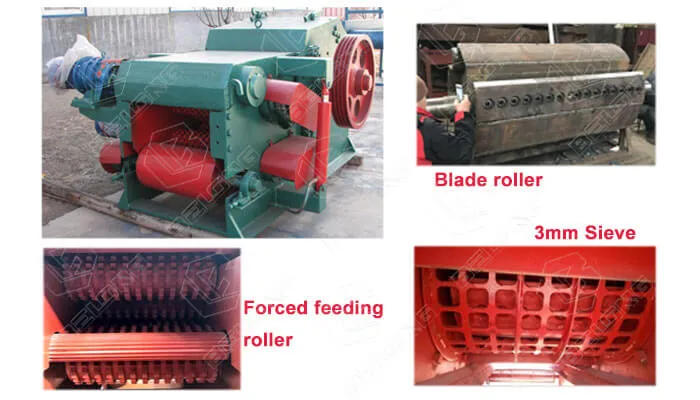

The drum chipper is composed of a base, a blade roller, an upper and lower feeding mechanism, a feeding belt conveyor, a hydraulic buffer system, a discharging belt conveyor, and an electrical control system. The chipper body is welded with a high-strength steel plate, which is the supporting foundation of the whole machine.

Blade and sieve of drum chipper

Unlike the disc chippers, the blades of the drum chippers are mounted on the cutter roller. 2-4 blades are mounted on the blade roller, and the blades are fixed on the blade roller by means of pressure blocks with specially manufactured blade bolts. According to the different thicknesses of the raw materials, the upper feeding mechanism can be opened and closed within a certain range with the help of a hydraulic system. The cut-qualified chips fall through the screen holes and are discharged from the bottom. The large wood chips will continue to be cut in the machine until they are finally discharged through the screen.

How the drum type wood chipper work

The advantages of drum chipper

There are several advantages of using a drum chipper:

1. High Production Capacity: Drum chippers are capable of processing large volumes of wood quickly and efficiently. They can handle logs of various sizes and shapes, making them ideal for use in commercial and industrial operations.

2. Consistent Chip Size: Drum chippers produce uniform chips of a consistent size, which is beneficial to the subsequent crushing process, improves the crushing efficiency, and reduces the wear of the blades and hammers of the wood crusher.

3. Versatility: Drum chippers can be used to process a wide range of materials, including wood, branches, and other organic materials.

4. Low Maintenance: Drum chippers are relatively simple machines that require minimal maintenance. They are designed to be durable and long-lasting, which makes them a cost-effective option for many businesses.

5. Safety: Drum chippers are designed with safety in mind. They have safety features that prevent accidents and injuries, such as guards and emergency stop buttons.

Technical parameter

| Model | Main motor power | Feeding motor power | Oil pump motor power | Conveyor motor power | Capacity | Inlet size | Blade quantity | Blade rotating speeding | Wood chips size | Dimension | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|

| BX-215 | 45kW | 2*2.2kW | 1.5kW | 3kW | 3-4t/h | 160*400mm | 2pcs | 590rpm | 22-30mm | 1470*1550*970mm | 3000kg |

| BX-216 | 55kW | 2*3kW | 1.5kW | 3kW | 7-8t/h | 230*500mm | 2pcs | 590rpm | 22-30mm | 1800*1900*1210mm | 4000kg |

| BX-218 | 110kW | 2*4kW | 1.5kW | 3kW | 12-15t/h | 300*680mm | 2pcs | 650rpm | 22-30mm | 2200*2150*1500mm | 7000kg |