Honeycomb coal briquette machine refers to the equipment for punching the coal or charcoal powder into cylinder briquettes. Its mold can be changed easily to produce different shapes and diameters beehive briquettes.

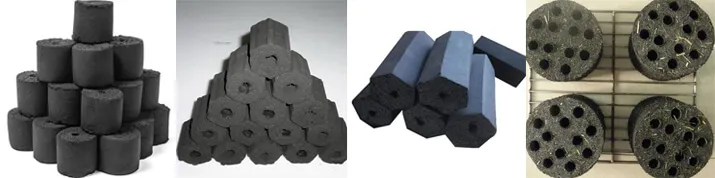

Different shapes and sizes of briquettes produced by the honeycomb briquette machine

Honeycomb coal briquettes are the main types of civil fuel in rural areas. It has been developed from cylindrical to square, polygonal, and concave shapes. There are various sizes of 100-250mm in diameter, with 12, 16, 19, 21 holes, etc. These holes improve convection, heat transfer performance, and the degree of coal burning, thereby increasing thermal efficiency. Besides, there are different molds for choice to make various shapes of coal briquettes. Both the shape and size can be customized.

Why Produce Honeycomb Briquette

Ordinary honeycomb briquettes use anthracite as the raw material. The upper ignition briquettes are processed with low-quality coal such as bituminous coal, lignite, and coal slime as the main raw materials and various combustible materials. In addition to home cooking and heating, it is also popularized and applied in canteens and catering industries.

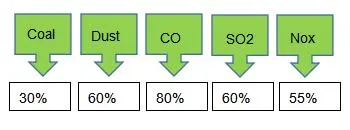

Combining briquette with advanced stoves, the thermal efficiency is 20%-45% higher than that of burnt coal. Generally, it can save coal by 20-30%, smoke dust by 40%-60%, and CO by 80%. After strengthening the sulfur agent, SO2 is reduced by 40%-60%, NOx is reduced by 55%, BaP is reduced by 90%, and the smoke blackness reaches Ringelmann 1/4 level. Significantly energy saving and environmental protection

Honeycomb coal briquett machine structure and design

The whole set honeycomb coal machine consists of machine body, transmission part, coal feeding part, stamping part, and belt conveying part.

1, The feeding part includes a rotating shaft, hopper, and mixer. Coal powder is mixed and filled into the mold.

3. The coal briquette press body consists of the platen, engine base, and frames.

5. After the honeycomb briquette is finished, the belt conveyor carries the briquettes out.

2. The stamping part consists of the slider, sliding beam, punch, base, punching head, active mold, and spring. The compacting degree of coal briquettes is determined by the punching pressure.

4. The transmission part includes an electric motor, pulley, gearbox, and transmission shaft. Electric motor drove the shaft to make the plate and rotating disc working.

What’s the difference with the charcoal extruder

How the honeycomb coal briquette machine work

Technical Parameters

| Model | BLMQ-120 | BLMQ-140 | BLMQ-160 | BLMQ-220 |

|---|---|---|---|---|

| Capacity | 45pcs/min | 45pcs/min | 45pcs/min | 45pcs/min |

| Honeycomb coal briquette diameter | φ100-φ120mm | φ100-φ140mm | φ100-φ160mm | φ180-220mm |

| Coal briquette height | 70-80mm | 70-80mm | 70-80mm | 70-80mm |

| Power | 5.5kW | 7.5kW | 7.5kW | 11kW |

| Belt rotating speed | 406r/min | 406r/min | 406r/min | 406r/min |

| Dimension | 1280*1160*1750mm | 1320*1260*1850mm | 1400*1300*2000mm | 1580*1450*2200mm |

| Weight | 1200kg | 1400kg | 2000kg | 4000kg |