Rotary dryer, also known as rotary drum dryer, is mainly used to dry various biomass raw materials in biomass briquettes production, such as sawdust, rice husk, bagasse, etc. The dryer used for drying wood shavings is a single-channel rotary dryer, which is made by slightly modifying the conventional sawdust dryer. It has high thermal efficiency, little damage to the shape of shavings, and a large production capacity. It can also be used for drying wood chips and bamboo chips produced by wood chippers.

The difference between sawdust rotary dryer and wood shavings rotary dryer

The reason why the wood shaving rotary dryer is slightly modified from the sawdust rotary dryer is that their overall structure is similar, and the main differences are in the way of discharging and the position of the fan.

The sawdust dryer is discharged through the cyclone, and the fan generates airflow to suck the dried sawdust into the cyclone and then discharge it through the airlock. The shavings rotary dryer is discharged at the end of the drum, and the dried shavings fall into the discharge port by their own weight and are discharged. Because the self-weight of shavings is much larger than that of sawdust, it needs a large airflow to drive the shavings out of the cyclone, and it is easy to damage the integrity of the shavings. It is the most suitable way to discharge materials by naturally falling at the end of the drum, which can not only save energy consumption but also greatly reduce the damage to the shape of shavings during the drying process.

Regarding the position of the fan, you can check the below picture. The Fan of the sawdust dryer is put ahead of the cyclone. The fan of the wood shavings rotary dryer is put at the end of the whole drying system.

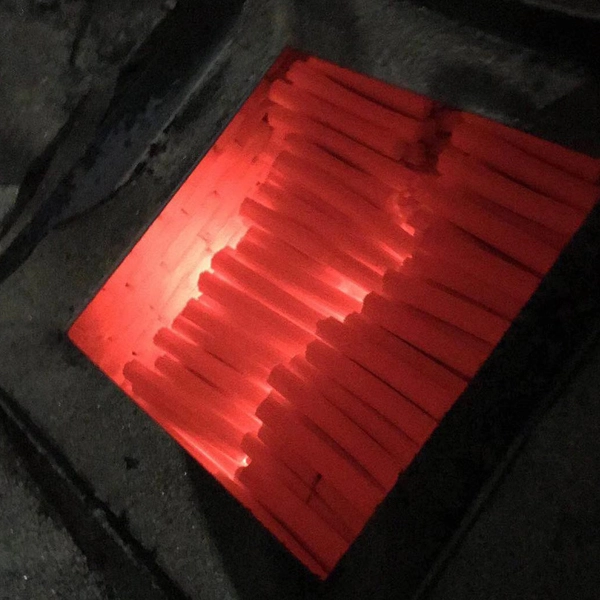

Check The Differences In The Below Pictures

Customized rotary dryer according to customer requirements

This American customer’s shavings have a humidity of about 45% and need to be dried to less than 12%. The output he requires is not high and only needs to dry about 250kg in one hour. Therefore we recommend the 800 model rotary dryer. And according to the customer’s requirements, we have customized the Siemens motor for the customer to ensure that the various indicators of the machine meet the local regulatory requirements. In addition, the customer also conducted a comprehensive inspection of our shavings dryer through a professional inspection company, and supervised the loading of the dryer when it was loaded into a container. Customers praised our company for the professionalism and good service throughout the cooperation process.