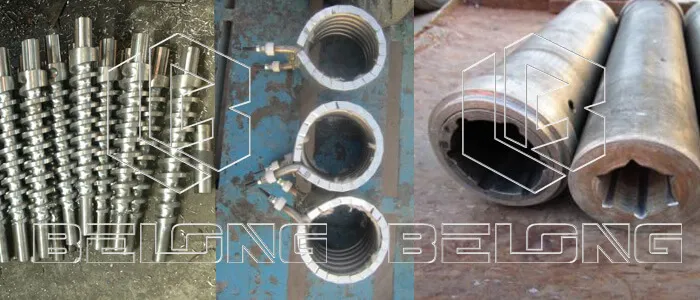

Wood briquette machine spare parts include the screw propeller, mold, and heaters. They are the key parts, as well as the quick-wear parts of the sawdust briquette machine. So in sawdust briquettes production, it is very useful to know well about the design, service life, and maintenance of spare parts.

Screw propeller

Screw propeller is an important part of wood briquette machine. Normally this spiral part should be dismounted to check after 3-5 days’ briquettes production. We suggest use wear-resisting and heat-resisting electrode for repairing.

Due to different raw materials, the continuous working time of the screw propeller is different. We can judge the wear of the propeller according to the working condition of the briquette machine. When the wood briquette machine has the following faults, the spiral propeller needs to be checked and repaired:

- 1The output speed of biomass briquettes was reduced significantly

- 2

The temperature and moisture content of the raw materials are all up to the requirements, but the briquette machine often gets stuck and cannot produce briquettes normally.

- 3

Sawdust briquettes can be formed, but they are detached one by one and cannot be connected together.

- 4Biomass briquettes are released quickly, but the structure is loose and the density is too low.

- 5

The inner diameter of the finished sawdust briquettes is less than 15mm

- 6

Due to entering foreign bodies such as stones and nails

How to repair the spiral propeller of a sawdust briquette machine

- 1

Preheat the part of the propeller which needs to be repaired, bring the temperature to about 200 ℃

- 2

2. Select wear-resistant electrode (707). According to the wear degree of the screw propeller, bead weld one layer first, remove the slag before the second layer is welded. The welding thickness exceeds the required thickness of 1-2mm. Welded propellers must not have defects such as slag inclusions and air holes.

- 3

3. Insert the welded part into dry quicklime or plant ash and make it.

- 4

4. Cool down to below 50 ℃ and take it out. Use a silicon carbide grinding wheel for grinding. Do not use excessive force or local overheating during grinding. Do not cool with water or other liquids.

- 5

5. There must be no potholes or unevenness on the front surface of the spiral after grinding.

Below is the video of repairing the spiral

Heaters (heating elements)

The Heaters are mounted on a mold, their function is to soften the lignin which is contained in the sawdust and other biomass materials. The heating coil adopts the principle of resistance wire heating, with low power consumption and short thermal energy accumulation time. The external materials of the heating ring are stainless steel, the middle layer is thermal insulation material, and the innermost layer has a high resistance of 1.8kW. One sawdust briquette machine is equipped with three heaters, which can heat instantly and make the temperature of mold quickly reach the set value.

The common faults of the heater

Q1. The heating ring is not burnt to red when it works

Q2. The heating speed is too slow

Q3. The temperature drops sharply after starting the briquette machine, and briquette machine is stuck

Q4. In these cases, you need to check working voltage of the heating coil is single-phase or three-phase. Generally, the three-phase electric heating coil connection method is the triangle method, and the single-phase electric heating method is the star connection method.

Correct wiring of heating coil of sawdust briquette machine

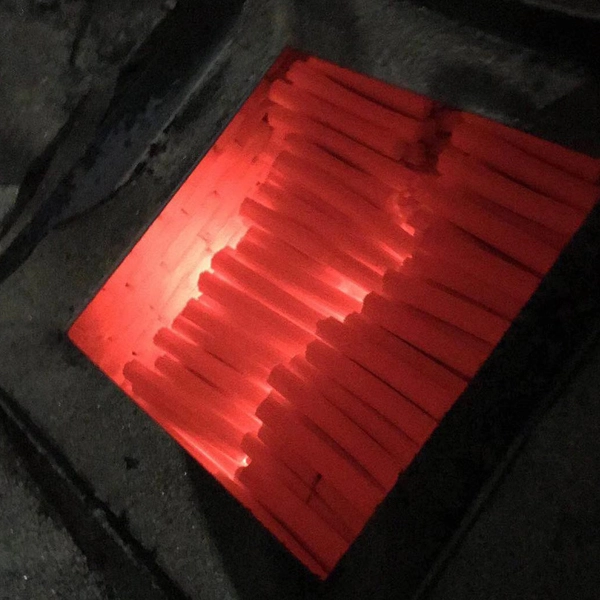

Mold

The mold is one of the important parts of briquette molding. Raw material can be shaped into the desired shape by it. The new type of wood briquette machine(ZBJ-II) improves the structure of the mold. After the structure of the mold is improved, the friction between the inner wall of the mold and the raw materials is reduced. This can increase the density of the wood briquettes. After the sawdust briquettes are carbonized into charcoal by the carbonization furnace, the burning time of the produced charcoal is also more durable.

The above is the detailed information of spare parts for sawdust rod making machine. If you have any need to purchase these accessories or have any questions about the briquette machine, please feel free to contact us.