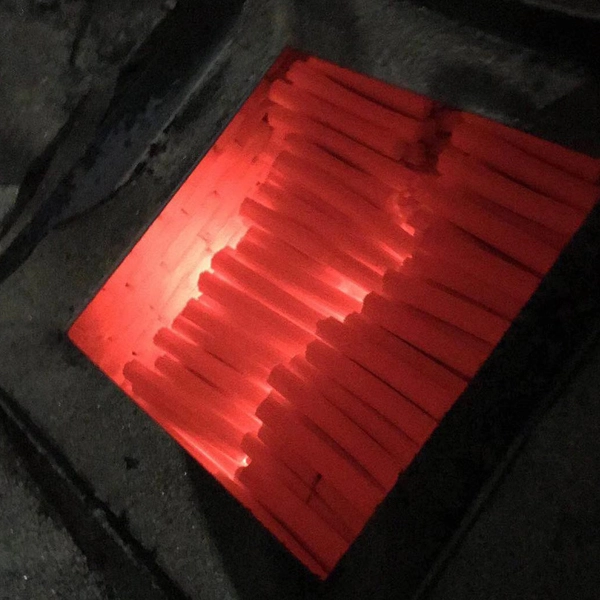

BBQ charcoal briquettes plant includes a complete charcoal-making process from raw materials carbonizing to charcoal briquettes production. BBQ charcoal is a hot sell on the market. It has the features of smokeless, less ash, longer burning time, and better commodity attributes.

BBQ charcoal briquettes production process

The process is Materials→carbonizing→crushing→mixing→briquetting. A complete BBQ charcoal briquettes production line includes the Carbonization stove, charcoal grinder, charcoal powder mixer, charcoal briquettes machine, dryer, packing machine and etc.

Materials suitable for this production process

From the above charcoal briquette production flowchart, you can find that the first is carbonizing. Therefore, only raw materials suitable for direct carbonization are suitable for this production process. Common materials that can be directly carbonized are wood, branches, bamboo, coconut shells, etc.

Additives for making BBQ charcoal briquettes

Charcoal powder is not sticky and requires the addition of a binder to make strong briquettes. Commonly used binders are tapioca and corn flour. They cost less than chemical binders and release less harmful substances when burned. One thing to note is that whether you use tapioca or corn flour, make them into a paste first, so as to achieve the best bonding effect

how much water and binder to add in making charcoal briquettes

For the 100kg charcoal powder, you can add 3-5 kg binder and around 45kg of water.

Produce briquettes of different shapes

We supply different types of charcoal briquette machines to make various shapes of charcoal briquettes. Please check the below picture.