Coconut shell charcoal application

Coconut shell charcoal is gradually becoming popular all over the world. As a totally natural, environmentally friendly biofuel, it can be used as a fuel substitute against fuelwood, kerosene, and other fossil fuels. Besides, it is also made into charcoal briquettes for shisha, cooking, BBQ, industrial boilers, etc.

Cheap and abundant coconut shell resource

People often discard the coconut shell after drinking coconut milk. In many tropical countries and regions that are rich in coconuts, you can see many coconut shells piled up on roadsides, markets, coconut processing plants, etc. In these places, you can get abundant coconut shell resources at a very low cost.

Basic factors for building a coconut shell charcoal factory

Besides the raw materials, you also need to ensure the power supply. The 3 phases industrial electricity is necessary for starting a charcoal factory. The other essential conditions like water, workshop, workers, etc, we don’t talk too much here. If you want to know more, you can contact us and tell us your requirements. We will provide you these details free for reference.

The above factors we mentioned are the foundation for starting a coconut shell charcoal business.

The next and also the most critical step is how to make charcoal briquettes from the coconut shell.

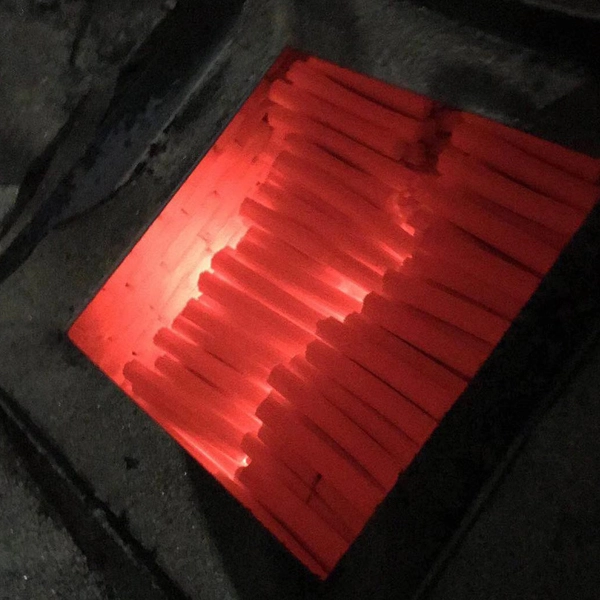

Carbonize coconut shell to charcoal

Coconut shells can be carbonized into charcoal directly by the carbonizing machine. We have different types of carbonization furnaces, almost all of them can be used for making coconut shell charcoal. For the small scale charcoal production, you can choose the hoist type and horizontal airflow carbonization furnace. For the big charcoal factory, you can choose the continuous carbonizing machine.

Coconut shell charcoal crushing

Coconut shell charcoal keeps the shell shape or break into pieces after carbonizing. Before making briquettes, you need to grind them into powder. Charcoal powder is much easier for shaping and can reduce the wearing of the machine.

Mixing charcoal powder with water and binder

As charcoal powder has no viscosity, we need to add a binder to help it form into briquettes. With a binder, the charcoal briquettes are more solid and the surface is more smooth. The most common binder is corn starch and cassava starch. They are food grade and have no noxious gas after burning. Usually, the binder ratio is 3-5%.

Regarding the charcoal moisture, it should be 20-25% after mixing. In production, there is a good method to know whether the moisture is okay or not. Grab a handful of mixed charcoal and pinch it by hand. If the charcoal powder does not come loose, the humidity has reached the standard.

Coconut shell charcoal briquetting

As we mentioned at the beginning of this article, the coconut shell charcoal can be used for shisha, BBQ, cooking, heating boiler, etc. How to make different shape charcoal briquettes to meet various purposes, click the below pictures of charcoal briquette machine to find more details.

Charcoal briquettes drying

All of the charcoal briquettes are wet after being produced by the charcoal briquette machine. So drying is necessary before they are used as fuel or sold on the market. No doubt there are two ways to dry the charcoal briquettes. One is natural drying in the sun, the other is drying by machine.

Natural drying

To prevent the soil or other impurities adhere to the surface of charcoal briquettes, we suggest you put the briquettes on a tray, plastic cloth, etc. And then it is better to put them on the shelf in case the rain or any unexpected damage. Usually, it takes around 4-7 days to dry the briquettes fully by natural drying.

Charcoal dryer

There are two types of dryers for drying charcoal briquettes: mesh belt dryer and box-type dryer.

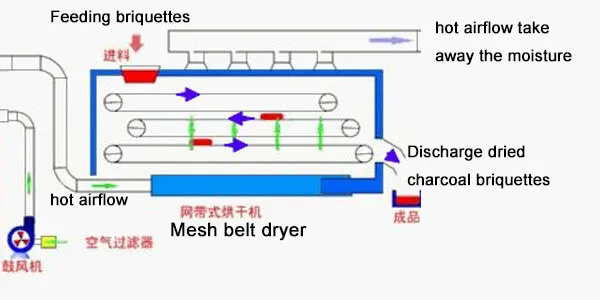

Mesh belt dryer

The whole drying process is fully automatic and only 2-3 hours. Charcoal briquettes are fed into the dryer by the conveyor. Inside the dryer, there are 3-4 layers or more mesh belts. Charcoal briquettes move very slowly from one layer to another. Hot airflow from the bottom to the top takes away the moisture.

Box-type charcoal dryer

The box-type charcoal dryer consists of a heating system, exhaust system, insulation house, shelves, and trays. Its drying theory is similar to airflow drying. Put charcoal briquettes on the tray and then place the tray on the shelf. The hot airflow takes away the moisture. You can choose combustion heating or electric heating. Drying time is around 5 hours, mainly affected by the heating temperature and charcoal briquette moisture.

Coconut shell charcoal advantages

- Coconut shell charcoal comes from a renewable resource, its production has zero impact on deforestation.

- Low ash residue

- Ashes can be used as fertilizer

- Burning time 3+ hours

- It burns hotter and longer than traditional charcoal

- Requires less charcoal for barbecues

- 1 lb. of coconut charcoal equals 2 lbs of traditional charcoal

- Clean burning