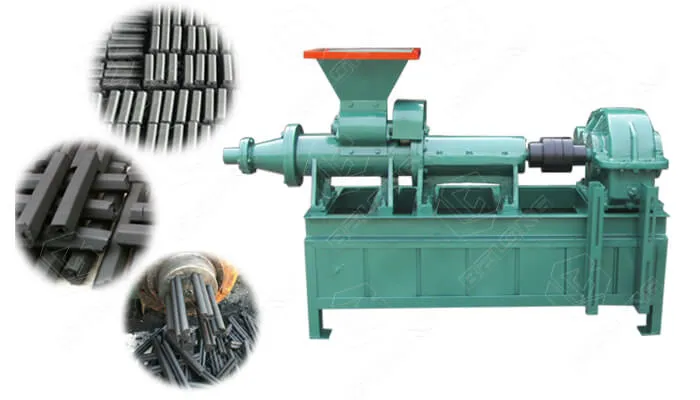

Charcoal extruder is a screw-type forming machine to produce rod shape briquettes from charcoal. As it also can be used for pressing coal, activated carbon, and semi-coke powder, it is also called a coal briquette machine. This machine has a compact design, including the electric motor, reduction box, feeding hopper, screw propelling part, discharging hole, machine base, etc.

Charcoal briquette extruder working principle

The charcoal extruder machine adopts the principle of screw extrusion to compress the coal or charcoal powder into shaped briquettes. After the charcoal powder is poured into the feeding hopper, it is propelled forward to the discharging hole of the briquette machine by the screw. From the screw chamber to the mold, space is becoming smaller. Under tremendous pressure, charcoal passes through the mold and finally forms certain shapes.

How the hexagonal charcoal rod extrusion machine work

Application of charcoal powder briquette machine

Besides charcoal and coal, this extruding machine can also produce briquettes from coke, sludge, olive pomace, cow dung, etc. For making good quality briquettes, charcoal powder size must be less than 5mm and moisture around 30%. To meet the requirements of different customers, the shape of charcoal briquettes can be hexagonal, square, circular, etc, the briquette’s diameter range is 3-50mm. Moreover, customers can choose to produce hollow or solid briquettes.

Charcoal briquettes cutter

To extend the application of the charcoal extruder machine, we usually equip it with an automatic cutter. It can cut the briquettes automatically to the same length. This small device increases production efficiency a lot and improves the appearance of the coal briquettes. Furthermore, with the help of an automatic cutter, the charcoal screw extrusion machine can be used for producing cubic shisha charcoal.

Charcoal extruder machine used to produce cube shisha charcoal

Technical Parameters

| Model | Power | Capacity | Diameter of charcoal briquette | Machine size | Machine weight |

|---|---|---|---|---|---|

| BLTB-140 | 11kW | 400-600 kg/h | 3-50mm | 2*1*1.1m | 700kg |

| BLTB-180 | 18.5kW | 800-1000 kg/h | 3-50mm | 2.2*1.2*1.2m | 1200kg |