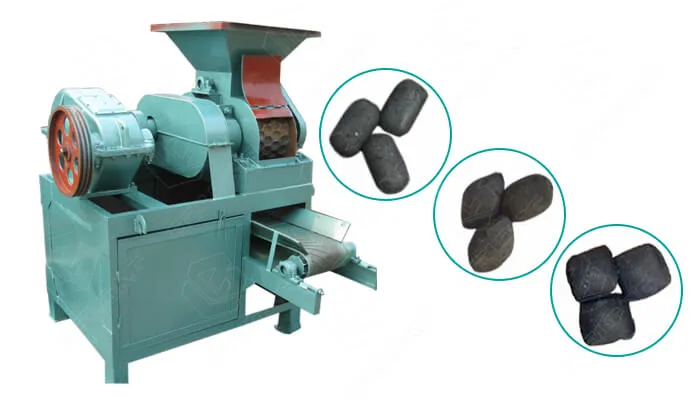

Pillow charcoal machine is a roller-type briquette press that can compress charcoal and coal powder into ball, oval, ovoid, egg, and pillow shape briquettes. It includes a pair of compression rolls with grooves, they are the main parts for the briquettes forming. It can produce different shapes and sizes of briquettes by changing the rolls of the pillow briquette press.

Materials for making pillow charcoal briquettes

The raw materials for making the charcoal briquettes need to meet the following requirements.

Charcoal powder

The size of charcoal materials must be less than 5mm. If you use lump charcoal, or coconut charcoal to make briquettes, you need to use a charcoal crusher to grind charcoal into powder.

Binder

After pulverizing charcoal to obtain charcoal powder, it is necessary to mix the charcoal powder with binder and water, and they can be mixed and stirred evenly with a wheel mill mixer. The common binder used for making charcoal briquettes is cornstarch and tapioca starch.

If use coal powder to make briquette, no need binder.

Humidity of charcoal powder

The suggested humidity of charcoal materials is around 30%. Charcoal briquettes producers need to adjust the humidity according to the quality of charcoal briquettes in actual production.

Different shapes of briquettes made by roller briquette press

The coal press machine can be widely used in different industries. Besides charcoal and coal powder, it can also be used for compressing and forming gypsum, mineral powder, metal powder, etc. The shape of briquettes can be oval, pillow, or customized.

Spare parts of charcoal briquette press

The compression roller is the key part of the pillow charcoal briquette machine. Because of the high pressure and friction with the charcoal powder and particles, it is also a vulnerable part. When we purchase the spare parts of the charcoal briquette press, in addition to the price, it is also important for us to know about its material, shape, size, design, and maintenance. We have an article especially talking about the Briquette Machine Press Roller.

Technical parameters of pillow BBQ charcoal machine

| Model | Capacity | Power | Size |

|---|---|---|---|

| BLYQ-290 | 2-3t/h | 5.5kW | 1.25*1.25*1.4m |

| BLYQ-360 | 3-4t/h | 7.5kW | 1.5*1.5*1.8m |

| BLYQ-430 | 4-6t/h | 15kW | 1.7*1.7*1.8 |