Charcoal mixer is used for mixing the charcoal powder with water and binder in charcoal briquettes production. There are two types of charcoal mixer, wheel-grinding mixer, and double-shaft mixer.

Wheel Grinding Charcoal Mixer

Wheel grinding mixer consists of a pair of rollers and a pair of shoveling plates. Charcoal particles are grinding into powder by the roller, and the carbon powder is blended with water and a binder evenly. It is ideal equipment for producing charcoal and coal rods, pressed pellets, honeycomb briquettes and etc.

Specifications of wheel grinding charcoal mixer

| Model | 1000 | 1200 | 1500 | 1800 |

|---|---|---|---|---|

| Diameter | 1000mm | 1200mm | 1500mm | 1800mm |

| Mixing capacity per time | 50kg | 80kg | 150kg | 200kg |

| Mixing capacity per hour | 200-300kg | 350-500kg | 600-900kg | 1000-1200kg |

| Power | 4kW | 7.5kW | 11kW | 15kW |

How the wheel grinding charcoal mixer work

First mix starch and water to prepare a binder and set aside. Pour a certain amount of charcoal powder into the charcoal powder mixer, add the corresponding amount of binder in proportion, then start the machine and mix the materials evenly. To ensure thorough mixing, it is recommended to stir for at least ten minutes.

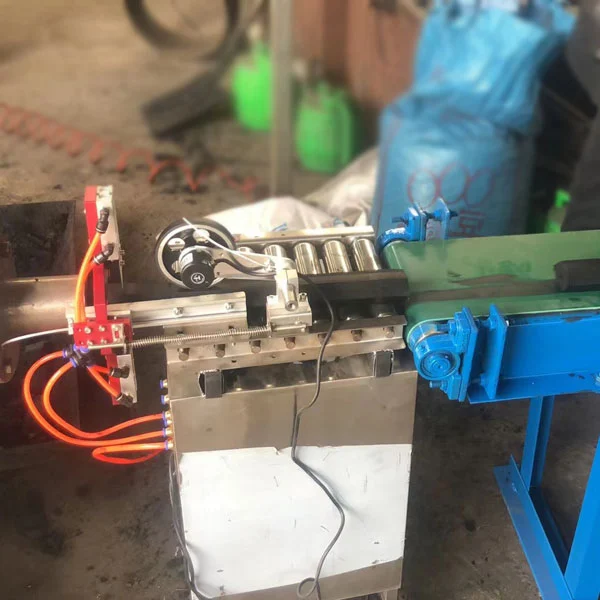

Double-shaft Coal Mixer Machine

Double-shaft mixer uses the synchronous rotation of two screw shafts to convey materials, and at the same time add water to mix, to achieve uniform humidification of materials and reduce dust. The humidified and mixed materials are easy to load and transport or transfer to the next processing equipment. It is mainly suitable for the humidification of coal, slag, and other similar materials in thermal power plants, mines, and other industries.

Technical parameters of double-shaft coal mixer machine

| Model | Capacity | Groove length | Paddle rotating diameter | Power |

|---|---|---|---|---|

| 350 | 10-15 t/h | 2000 mm | 350 mm | 7.5 kW |

| 400 | 20-40 t/h | 2500 mm | 400 mm | 11 kW |

| 500 | 20-50 t/h | 2500 mm | 500 mm | 18.5 kW |

| 600 | 30-80 t/h | 3000 mm | 600 mm | 22 kW |

| 700 | 40-100 t/h | 3000 mm | 700 mm | 30 kW |

| 1000 | 120-200 t/h | 3000 mm | 1000 mm | 45 kW |