The sawdust dryer is specially designed for drying the biomass materials, such as wood sawdust, small wood chips, rice hull, sunflower husk, peanut shells, etc. Depending on the different drying principles, sawdust dryers are classified into two types, sawdust flash dryers, and rotary drum dryers.

Why the sawdust dryer is necessary

As we know, the ideal water content of materials is 8%-15% for producing biomass briquettes and pellets. Usually, the moisture of the untreated ingredients is 30%-60%, and fresh sawdust from the sawmill can reach more than 80%. Even if these materials are air-dried enough, the water content can be reduced to 20% at most, but they still can’t meet the requirement for producing briquettes. So it is necessary to dry the materials before making sawdust briquettes.

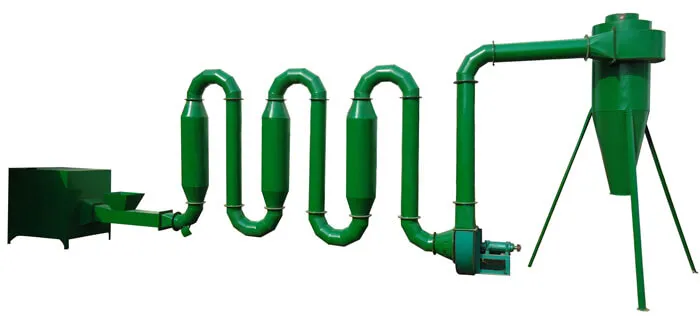

Sawdust Flash Dryer

Sawdust flash dryer includes heating stove, pipes, fan, and cyclone. It is also called airflow dryer or pipe dryer. Wet sawdust enters the airflow dryer through the feeding hopper, they are mixed with the hot air by the airflow force of the electric fan. Sawdust flows through the curved pipes and finally enters the cyclone. At last, water vapor of sawdust is taken out by the hot air and expelled out from the up outlet of the cyclone, and sawdust is discharged from the down outlet.

Features of biomass flash dryer

- Biomass materials range and size: rice husk, wood sawdust, wood shavings, crushed tree branches, small wood chips, etc. Diameter is less than 3mm, length is less than 5mm.

- Thermal efficiency: Because the material is highly dispersed in the air flow, the contact area between the material and hot air is large, so the drying time is short, the processing capacity is large, and the thermal efficiency is high. When drying unbound water, the thermal efficiency can reach 60%.

- Fuel for heating: waste wood, coal, steam and electric heating.

- Installation space is small: The hot airflow dryer is pipe structure, it can be installed in line and also can be fold installation to save the space.

Technical parameters of airflow biomass dryer

| Model | Capacity | Power | Dimension | Weight |

|---|---|---|---|---|

| BLGH-220 | 300-400kg/h | 4kW |

2.25*1.05*1.3m 1.4*0.8*1.45m |

960kg |

| BLGH-320 | 400-800kg/h | 7.5kW |

2.45*1.72*1.91m 1.45*1.42*1.41m |

1500kg |

How The Sawdust Airflow Dryer Work

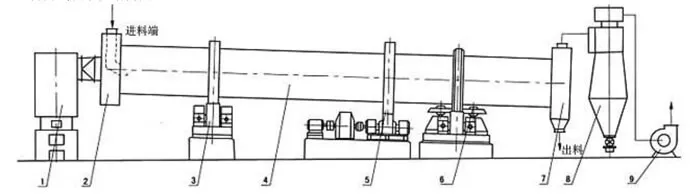

Rotary Drum Sawdust Dryer

Rotary drum dryer includes: 1. Hot air stove 2. Feeding hopper 3. Carrier roller 4. Dryer chamber 5. Electric motor driving 6. Carrier roller 7. discharging port 8. Cyclone separator 9. fan

In additional, we can customize the heating device, and equip elevator, conveyor, constant weight feeding machine, and etc.

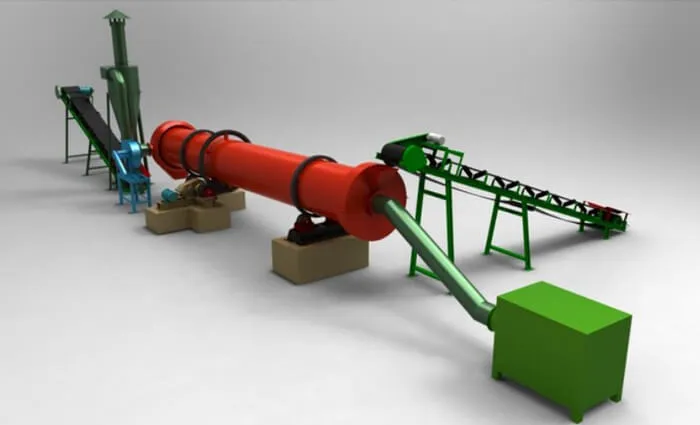

Working principle of rotary dryer

- Dryer cylinder is inclined at a small angle (3-5 °) from the horizontal line.

- Wet material is sent to the feeding hopper by conveyor or elevator, and hot airflow enters the cylinder together with material. As the cylinder rotates, material gradually moves from the higher end to the lower end under the effect of gravity.

- There are many shoveling plates welded on the inner wall of the cylinder. Their function is to shovel and scatter the material to increase the contact surface between material and air flow, to increase the drying rate, and to promote the material moving forward.

- During the forward movement of the wet material, hot air is continuously heating to dry the wet material.

- Finally, the cyclone dust collector collects the materials carried by the gas, the exhaust gas and water vapor are discharged from the upper outlet, and the dried materials are discharged from the lower outlet.

Rotary drum sawdust dryer working video

Technical parameters of rotary drum dryer

| Model | Power | Capacity | Rotating speed | Gradient |

|---|---|---|---|---|

| BLZH-800 | 3+7.5kW | 0.8-2t/h | 3-8r/min | 3-5° |

| BLZH-1000 | 3+15kW | 1-3t/h | 3-8r/min | 3-5° |

| BLZH-1200 | 4+18.5kW | 2-5t/h | 3-8r/min | 3-5° |

| BLZH-1500 | 4+22kW | 3-8t/h | 3-8r/min | 3-5° |