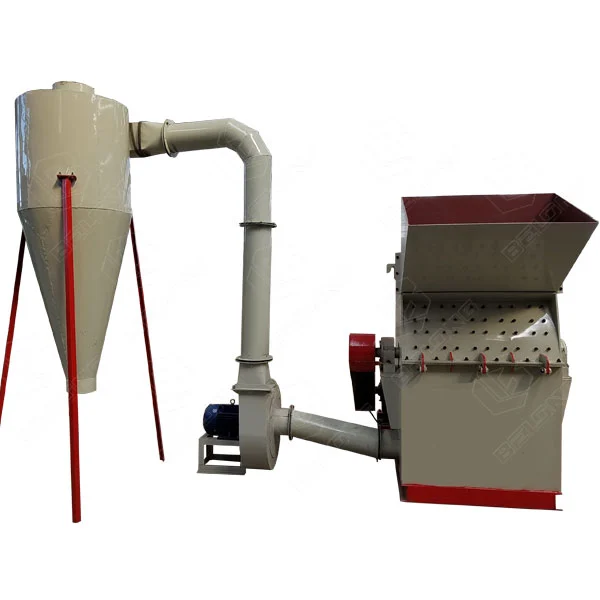

Wood shavings machine is mainly used for mass production of flake shavings with uniform thickness. The output of the machine is 300-2000kg per hour, whether it is for domestic or commercial use, there are suitable models to choose from. In addition, our wood shavings machine can be made fixed or movable and can be electric or diesel-powered to meet different customer needs.

The working principle of the wood shavings machine is simple. Wood material enters the feeding port and enters the crushing chamber after being cut by the blade. The wood shavings are cut by the blade and crushed by the impact of the high-speed rotating hammer. Finally, under the action of the wind generated by the built-in fan blades, wood shavings are sent out of the discharge port through the screen. The size and thickness of the wood shavings can be changed by adjusting the blade length.

Wood shavings can be used as bedding for horses, chickens, rabbits, and other animals and poultry, as fillings for the transportation of fragile goods, as raw materials for particleboard (plywood), papermaking, and for the production of biomass fuel, etc.

If the wood shavings are wet or moist, they are not good for storage and can’t be used at once. It is important to dry them before using them for various purposes. The rotary drum dryer is one of the equipment for drying wood shavings.

Technical parameters

| Model | Power | Capacity | Inlet size | Balde quantity | Spindle speed | Dimension | Weight |

|---|---|---|---|---|---|---|---|

| BH-420 | 7.5/11kW | 300kg/h | 140*100mm | 4pcs | 500RPM | 1.2*0.5*0.7m | 200kg |

| BH-600 | 15/18.5kW | 500kg/h | 140*150mm | 4pcs | 450RPM | 1.55*0.63*0.95m | 380kg |

| BH-800 | 30/37kW | 1000kg/h | 190*220mm | 8pcs | 400RPM | 1.85*0.8*1.4m | 800kg |

| BH-1200 | 55kW | 1500kg/h | 220*300mm | 8pcs | 400RPM | 2.4*1*1.4m | 1150kg |

| BH-1500 | 75kW | 2000kg/h | 320*420mm | 12pcs | 400RPM | 3*1.2*1.8m | 1600kg |