Disc wood chipper is a wood processing machine for cutting or chipping wood materials into small to medium-sized wood pieces. It features a steel disc and Alloy cutting blades. The size of wood chips is 15-35mm.

Compared with drum chippers, disc wood chippers are smaller in size, and lower in price. The disc wood chipper can be made into a fixed type or a mobile type, and the power can also be made into an electric drive or a diesel drive. Its use scenarios are wider. They can also be customized according to the requirements of different customers.

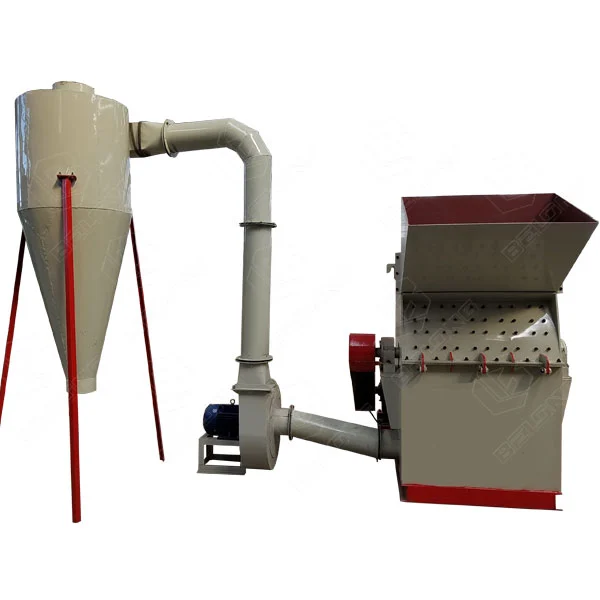

The following are the different types of disc wood chippers

Wood chips are widely used in both industry and agriculture

1. Wood chips are the raw material of density board

2. Wood chips can be made into machine-made charcoal

3. Biomass pellets

4. Raw materials for paper making

5. Culture medium for edible fungi

6. Use as compost

7. Garden mulch

8. As a soil and water conservation raw material that absorbs water

| Model | Power | Capacity | Feeding port size | Disc diameter | Spindle speed | Blade quantity |

|---|---|---|---|---|---|---|

| BLXP-420 | 7.5kW | 0.5-1t/h | 15*15cm | 420mm | 600r/min | 3pcs |

| BLXP-600 | 15kW | 1-2t/h | 15*18cm | 600mm | 600r/min | 3pcs |

| BLXP-800 | 30kW | 2-4t/h | 20*20cm | 735mm | 550r/min | 4pcs |

| BLXP-950 | 37kW | 4-6t/h | 23*25cm | 830mm | 550r/min | 4pcs |

| BLXP-1150 | 75kW | 6-8t/h | 30*33cm | 1150mm | 600r/min | 4pcs |

| BLXP-1410 | 110kW | 8-10t/h | 40*40cm | 1410mm | 600r/min | 4pcs |