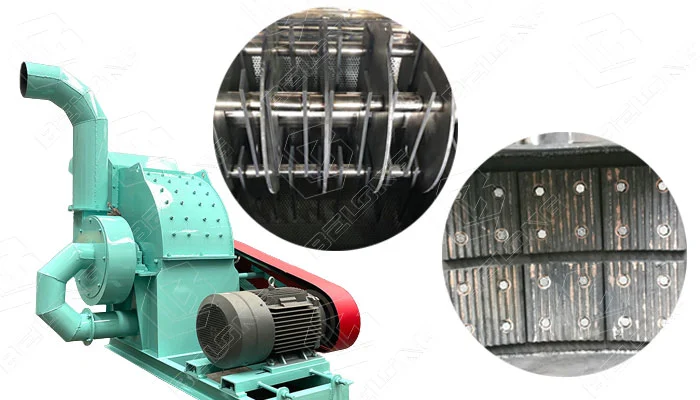

Wood hammer mill is another sawdust making machine. Its main function is to crush large-sized wood chips into 3-5mm sawdust for the production of wood pellets and sawdust briquettes. Compared with the blade-type wood crusher, it has no blades and relies on the high-speed rotation of the hammers inside the machine to hit the biomass materials and crush the materias into fine sawdust.

Hammer wood mill crusher working principle

A hammer wood mill is mainly composed of a machine shell, shaft, hammers, screen, wear-resistant liner, draught fan, cyclone, and etc.

When the hammer mill crusher is working, the motor drives the rotating shaft to rotate, and the hammers on the rotating shaft will also rotate at high speed along with the rotating shaft. The wood material is sent into the crushing chamber from the feeding port and will be crushed soon under the impact of the high-speed rotating hammers. If the crushed material reaches the required fineness, it will be sent to the discharge port through the screen by airflow, otherwise, it will remain in the crushing chamber until it is crushed to the required size. For large-capacity hammer mill machines, we usually equip an independent fan to assist with the discharge of sawdust.

Materials that can be crushed by wood hammer mill

- The raw materials with sticky, oily, or too high water content are not suitable for processing with a hammer mill crusher

- Wood with a diameter of more than 4cm or a thickness of more than 4cm is not suitable for crushing directly with a hammer crusher. Generally, we recommend working with a wood chipper machine. First, use a wood chipper to cut the thick wood into wood chips, and then smash the wood chips into sawdust with a hammer mill. This can not only improve the yield but also reduce the machine’s loss.

- In addition to the common wood, bark, wood chips, shavings, templates, etc., the hammer mill can also crush the crop stalk, corn, nutshell, peanut shell, etc.

Spare parts of wood hammer mill

The hammers and screens are the spare parts of the hammer mill machine that we often recommend customers buy with it.

The hammers are the main working part of the hammer mill, which has a great influence on the crushing performance. There are many shapes of the hammer, the common ones are rectangle, step shape, sharp rhombus, and so on. Because the crushing performance of rectangular hammers is better than other types of hammers, most of our hammer milling machines use rectangular hammers.

The edges and corners of the hammer are usually welded with a special wear-resistant alloy. Compared with ordinary hammers, although the cost is increased, the exchange is a longer service life and higher crushing efficiency. The hammer usually has one or two pinholes, which can be exchanged for use, prolonging the working period of the hammer.

The main function of the screen is to control the size of the output. Finished products of different sizes can be produced by replacing screens with different apertures.

Different types of wood hammer mill

Electric wood hammer mill and Diesel hammer crusher

According to different driving methods, the hammer mill can be divided into electric type, diesel type, PTO driven type, etc. A base with wheels can also be added for easy movement.

Technical parameters of electric wood hammer mill

| Model | 500 | 600 | 800 |

|---|---|---|---|

| Hammer quantity | 40pcs | 50pcs | 70pcs |

| Hammer thickness | 6mm | 8mm | 8mm |

| Driving motor | 22kW | 37kW | 55kW |

| Fan motor | 7.5kW | 7.5kW | |

| Capacity | 500-1000kg/h | 1000-1500kg/h | 1500-2000kg/h |

How the electric wood hammer mill machine work

Large wood chips crusher

A large hammer mill is usually composed of a wood chipper, a conveyor, a hammer mill, a cyclone, an airlock, a dust bag, etc. It is mostly used for large-scale wood pellet production, etc.

Technical parameters of large wood hammer mill

| Model | 1000 | 1300 | 1500 |

|---|---|---|---|

| Swing diameter | 720mm | 820mm | 920mm |

| Hammer quantity | 70pcs | 126pcs | 140pcs |

| Hammer thickness | 8mm | 8mm | 8mm |

| Feeding port size | 800*350mm | 1000*400mm | 1300*450mm |

| Main shaft speed | 2200r/min | 2000r/min | 1800r/min |

| Driving motor | 75kW | 90kW | 110kW |

| Fan motor | 7.5kW | 11kW | 15kW |

| Capacity | 2500-3000kg/h | 3500-4000kg/h | 4500-5500kg/h |