During the communication with customers, we find that many customers make a mistake that the carbonization furnace can also produce activated charcoal. Though the two products names all include “charcoal”, actually there are many differences between them. Below are the differences between wood charcoal and activated carbon I collected, hope they can give some help to the friends who are interested in it.

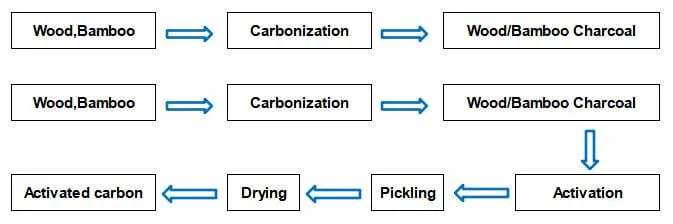

Different processing techniques

In terms of composition, the raw materials of both are wood, coconut shell, and other wooden raw materials, but as sand is much more complicated than glass, the production process of activated carbon is much more complicated than charcoal. Wood charcoal only passes through the carbonization stage, but the activated carbon is subjected to activation, pickling, and drying stages in addition to the carbonization process.

Micro-structure is different

The pore diameter of charcoal is larger than that of activated carbon. The large/medium/small holes in the charcoal are ducts, vascular bundles, and small holes in the sidewalls of the thin-walled tissue. The pores of charcoal are mainly macropores, and their diameters are mainly around 200 nm. The pores of activated carbon are mainly micropores, and the pore diameters are divided into three categories: macropores (≥50nm), which account for 10-30% of the total pore volume, and micropores (≤2nm) account for about 60%-90% of the total pore volume, the mesopores are also called transition holes (2nm ≤ φ ≤ 50nm), accounting for about 5 to 7% of the total pore volume. The average pore diameter of activated carbon is about 1.5 nm. The molecular diameter of harmful gas: formaldehyde 0.44 nm, benzene 0.48 nm, ammonia 0.414 nm, toluene 0.58 nm, xylene 0.60 nm, methane 0.324 nm, etc. So it can be seen that bamboo charcoal has no adsorption and purification function for these harmful gases, but the diameter of the molecule of activated carbon is indeed combined with these harmful gases, so its adsorption performance and an impediment to harmful gases are better.

The specific surface area is not the same size

The specific surface area refers to the amount of surface area occupied by the unit mass. That is the sum of the surface area of 1 gram of carbon and all pore areas. The bamboo charcoal having a carbonization temperature of 500 ° C or higher has a specific surface area of between 150 m 2 /g and 350 m 2 /g. The activated carbon prepared by physical or chemical activation can have a specific surface area of 900 m 2 /g or even 2000 m 2 /g or more. Due to the more developed pore structure, the larger the specific surface area, the stronger the adsorption function, so the activated carbon is more strongly adsorbed than bamboo charcoal.

Different hardness

Bamboo charcoal has high density, high hardness, and is not easy to be broken. It is suitable for wear-resistant home textile products. The hardness of activated carbon of different materials is very different, the hardness of activated carbon of coconut shell is high, and the activated carbon produced by bamboo has lightweight, softness, and brittleness, so it is not suitable for products with high wear resistance.

Production costs vary widely

Charcoal requires only one carbonization process, and activated carbon requires an activation process, which is much higher than charcoal, about 3-5 times that of charcoal. Therefore, the price of the product is 3-5 times that of charcoal.

Raw material consumption is different

The raw material consumption of activated carbon is generally 3-5 times higher than that of bamboo charcoal. For example, 6t (ton) bamboo can be charred to produce 1t bamboo charcoal, but 3-5t bamboo charcoal can process 1t bamboo activated carbon. Of course, the raw material cost of coconut shell activated carbon will be higher, but the effect is better.

Different shapes

Charcoal is in a variety of ways, including charcoal, flake carbon, broken charcoal, granular charcoal, charcoal powder, and so on. Activated carbon is generally only in the form of powder (diameter ≤ 0.18mm) and granular (diameter ≤ 8mm). Because there is no bulk activated carbon, its application is greatly limited.