Biomass materials for making charcoal

Biomass materials include forest wastes, agricultural wastes, etc. Materials like coconut shells, waste wood, branches, bamboo, etc can be carbonized into charcoal directly. Some materials like sawdust from sawmills, furniture factories, bamboo sawdust from toothpick factories, etc, are not suitable for carbonization directly. How to make charcoal from sawdust? We need to adopt the charcoal production process of biomass charcoal briquettes plant.

Biomass charcoal briquettes plant consist of crusher, dryer, biomass briquette machine, carbonization machine, etc. The process of biomass charcoal making is biomass materials→ biomass briquettes→ charcoal. Materials like wood sawdust, bamboo wastes, rice husk, etc are suitable for this method. These materials are small in size, soft, and burn to ash easily. Making briquettes first can reduce the loss of materials in the carbonizing process. The whole process is indicated in the below picture.

Machines for making biomass charcoal briquettes

Crusher

Sawdust, rice husk can be used directly for producing briquettes. But some big size biomass materials such as waste wood, cotton stalks, they need to be crushed to 3-5mm size. We can equip the crusher for processing these materials.

Drying Machine

For producing biomass briquettes, the materials moisture must be less than 12%. If the materials are wet, we can use a dryer to dry the materials efficiently. There are two type dryer, airflow type for small capacity, and rotary drum dryer for big capacity.

Biomass Briquette Machine

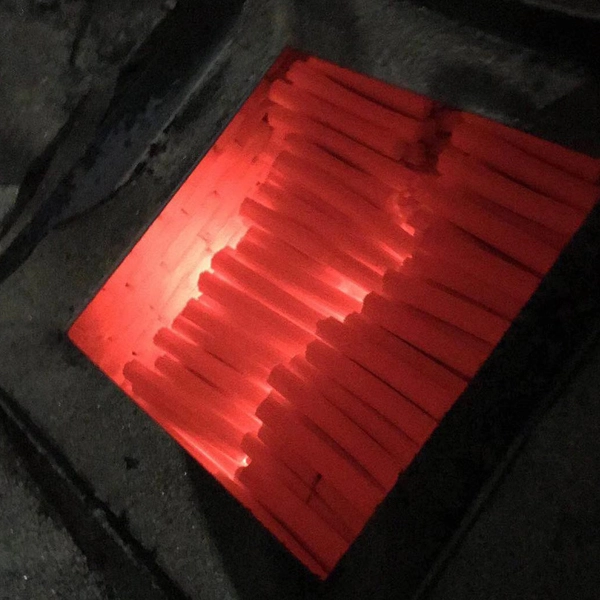

After the materials are dried, they can be made into briquettes by the briquette machine.

Carbonization machine

There are different types of carbonization furnaces for converting biomass briquettes to charcoal briquettes. You can visit the page of carbonizer machine for more details. The recommended carbonization furnace is vertical type and horizontal type.