Good raw materials are the basis for the production of high-quality charcoal. In theory, many biomass can be used to produce charcoal, such as sawdust, bamboo powder, rice husk, bagasse, and so on. But it needs to be clear that under the same conditions, the quality of the carbon produced by different materials is different. So what is the best raw material for making charcoal?

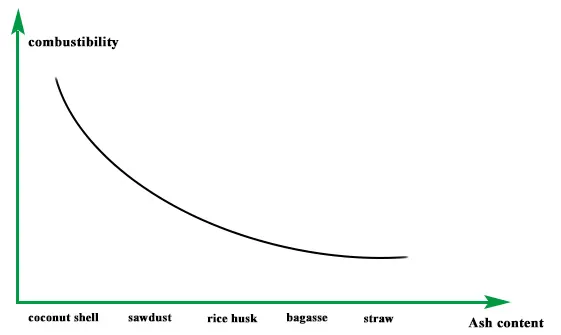

Studies have shown that ash content directly affects the combustion performance of biomass charcoal. The lower the ash content, the better the combustibility of charcoal. The data tested by agricultural experts show that: coconut shell ash content is 0.61%, sawdust ash content is 0.9%, cotton stalk ash content is 5.1%, rice husk ash content is 15%, and straw ash content is 19.1%. Therefore, it is easy to get the result that coconut shell and sawdust are the better materials for making charcoal briquettes.

For sawdust, there are hardwood sawdust and softwood sawdust. Poplar, paulownia, eucalyptus, etc. This type of wood has a loose wood structure and is collectively referred to as softwood. The charcoal made from softwood is not very good in burning performance. Slow-growing pine, oak, fir, oak, bamboo, etc. are hardwoods, and the charcoal produced is better combustible performance than softwood charcoal.

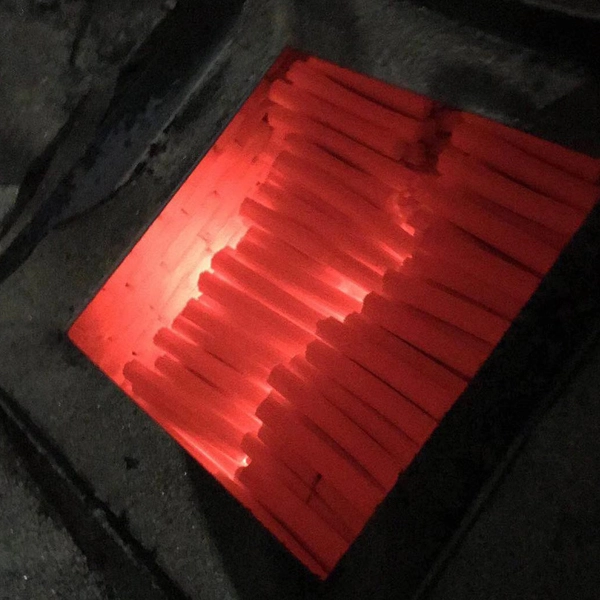

Therefore, in terms of the quality of charcoal alone, coconut shells, hardwood, and bamboo shavings are the best raw materials, followed by rice husk and bagasse. But this is not the final answer to the question. Because the needs of the terminal are diverse, we often say that the appropriate is the best, and products of different quality have their own markets. Barbecue charcoal or hookah charcoal has higher requirements on the quality of charcoal, requiring low ash content, long burning time, and no smoke. The price of this type of charcoal is the highest. One of the main reasons is the cost of raw materials. The price of hardwood is much higher than that of softwood, waste wood, branches, and rice husks. For some common heating purposes, such as boiler burning, cooking, etc., ordinary charcoal can be satisfied, and there is no need to use the best charcoal to increase the expenditure.

In the end, the original intention of the charcoal machine is to replace raw wood charcoal, reduce tree felling, and produce charcoal at a very low raw material cost, thereby obtaining economic benefits. Therefore, customers who want to invest in the charcoal business must understand their raw material sources, costs, and target markets based on their own circumstances.