Can I make charcoal from bamboo wastes from my toothpick factory? This is the beginning of the conversation between a Columbia customer and us. The customer owns a toothpick factory and they process tons of bamboo every day. In this factory, there is a lot of bamboo waste, like bamboo shavings, powder, dust, and scraps.

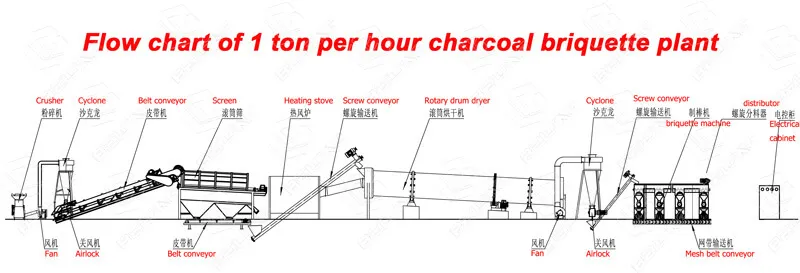

He was thinking about how to take advantage of these bamboo wastes instead of discarding or burning them. So he looked for the method and solution on the internet and found our company. Through discussion, we understand his demands and provided him with this charcoal production line solution of one ton per hour accordingly.

Design of bamboo wastes charcoal production line

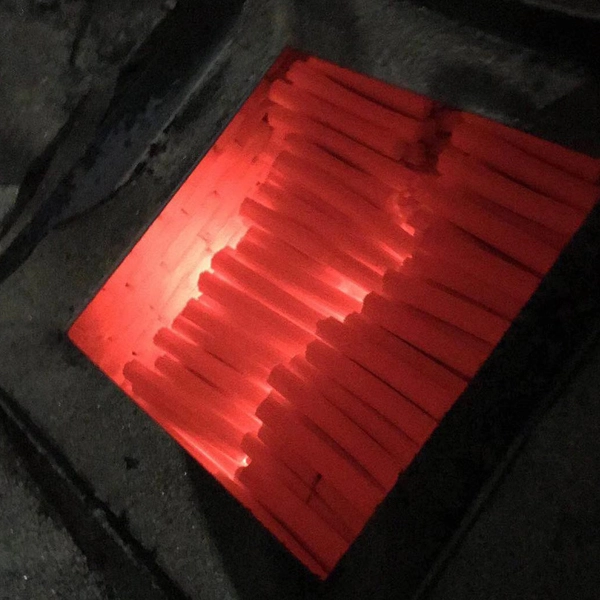

- Make briquettes first, then carbonizing. As the bamboo sawdust and scraps are not suitable for carbonizing directly, we make them into briquettes first, then carbonize the briquettes into charcoal. Maximize the use of raw materials and reduce wastage.

- Choose hammer crusher. It is the best for crushing the bamboo joints, bamboo chips, scraps, etc.

- Bamboo sawdust drum screen. It can help screen out the big size bamboo waste, and increase the efficiency of the following sawdust drying and briquetting.

- Automatic design, save the labor cost.