How to make BBQ charcoal? For many people who want to try to produce BBQ charcoal, this is the first question before them. With the popularity of barbecue all over the world, the market demand for BBQ charcoal has also increased, and the business of producing BBQ charcoal has gradually attracted the attention of investors. This article introduces the relevant information in detail from the raw materials for making barbecue charcoal, the types of barbecue charcoal, the production process, and the equipment involved.

The raw materials for making BBQ charcoal

Wood

Wood is the most common raw material for producing BBQ charcoal, including hardwood, miscellaneous wood, fruit wood, etc. These woods can be used to produce natural charcoal without any additions. Most of them retain the shape of the logs themselves, are easy to ignite, and emit a natural firewood smell when grilling. The more famous ones are Machi charcoal, oriental white oak charcoal, chrysanthemum charcoal, longan charcoal, lychee charcoal, and so on.

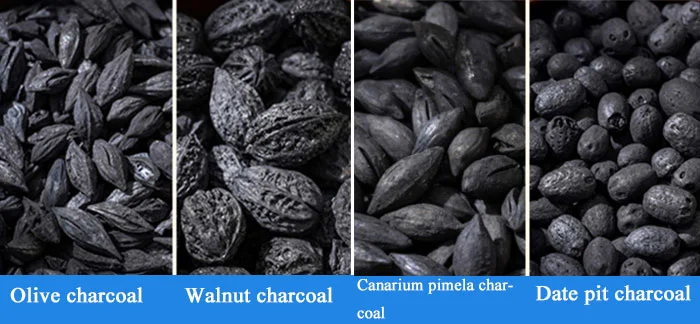

Nutshells and fruit cores

The common ones are black olives, walnuts, olives, date pits, and coconut shells. The charcoal made from these raw materials can emit the unique fragrance of the raw materials when burned.

Woody debris

Wood scrap, such as sawdust, shavings, bamboo chips, rice husks, etc. These raw materials are mostly used for the production of machine-made charcoal and charcoal briquettes.

Natural charcoal or Charcoal briquettes

Natural charcoal or charcoal briquettes, this is a question. First, we need to understand the difference between the two.

Shape

Natural charcoal basically retains the shape of the raw materials, most of which are irregular. Charcoal briquettes, on the other hand, are machine-produced, uniform in shape and size.

Additive

Natural charcoal is directly carbonized from raw materials. There is only one process of carbonization without any additives. To make charcoal briquettes, the needed process is carbonization, crushing, mixing with additives, and extruding.

Burning time

Since natural charcoal is directly carbonized from raw materials, its texture is relatively loose, and most natural BBQ charcoal does not burn as long as BBQ charcoal briquettes. The burning time of most natural charcoal is about 1.5 hours, and the burning time of charcoal briquettes is about 3 hours. Of course, there are exceptions for some high-quality natural charcoal. For example, binchotan has a longer burning time than machine-made charcoal, and the burning time can reach more than 4 hours.

BBQ charcoal production process

The production process of BBQ charcoal needs to be determined according to the specific raw materials. Below we will introduce one by one according to different raw materials.

Production process of natural BBQ charcoal

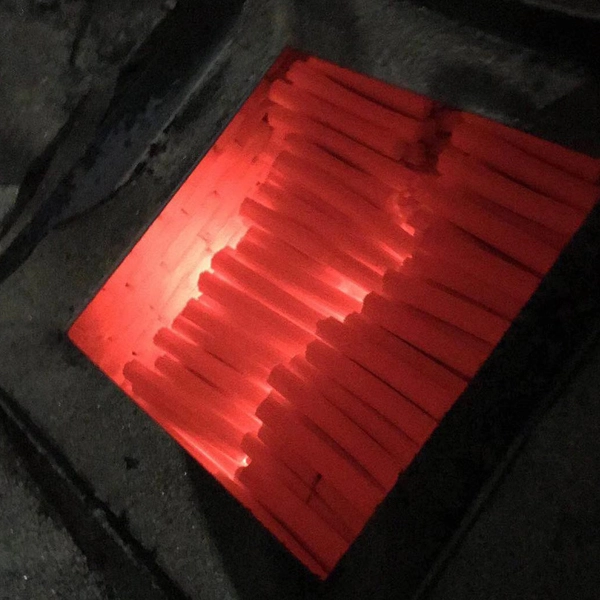

As mentioned above, there is only one process in the production of natural charcoal, which is carbonization.

Regarding natural BBQ charcoal production, there are two points that need to be mentioned. One is that the moisture content of raw materials should not be too high, it is best to keep it below 30%, the drier the better. Because the drier the raw material, the shorter the time required for dehumidification during the carbonization process, and the less fuel consumption. The other is that properly prolonging the carbonization time and temperature can effectively improve the quality of BBQ charcoal.

Production process of BBQ charcoal briquettes

Regarding the production process of charcoal briquettes, we need to introduce them separately according to different raw materials. In the previous raw material section, we introduced the common raw materials for making barbecue charcoal, including wood, coconut shell, nut shell, wood scraps, sawdust, and so on.

For raw materials that can be directly carbonized, such as wood, coconut shell, etc

The production process of charcoal briquettes is as follows,

1. Carbonize wood or nutshell to charcoal

2. Crush charcoal into charcoal powder

3. Mix charcoal powder with water and binder

4. Make charcoal briquettes

For raw materials that are not suitable for carbonization directly, such as wood scraps, sawdust, etc

The production process of charcoal briquettes is as follows,

1. Crush big-size wood scraps into sawdust (<5mm)

2. Dry the sawdust, making sure its moisture is <12%

3. Convert sawdust into briquettes

4. Carbonize sawdust briquettes to charcoal.

BBQ charcoal machines

Carbonization furnace

Carbonization furnaces are required for the production of both natural BBQ charcoal and BBQ charcoal briquettes. So we introduce it first.

The carbonization furnace is divided into vertical type and horizontal type. The vertical carbonization furnace has a wide range of applications and is suitable for the carbonization of all kinds of raw materials. The horizontal carbonization furnace is suitable for the carbonization of materials with a longer length and easy placement, such as branches, bamboo, sawdust briquettes, etc.

Charcoal pulverizer

Charcoal pulverizer is an auxiliary equipment in the production of charcoal briquettes. The main function is to crush the block charcoal into charcoal powder, and then the best effect can be achieved in the next step of stirring and mixing.

Charcoal powder mixer

As another auxiliary equipment in the production of BBQ charcoal briquettes. The main function of the carbon powder mixer is to mix the carbon powder with water and additives evenly.

BBQ charcoal briquettes machine

Common barbecue charcoal on the market has various shapes, but basically, they are produced by the following two charcoal briquette machines.